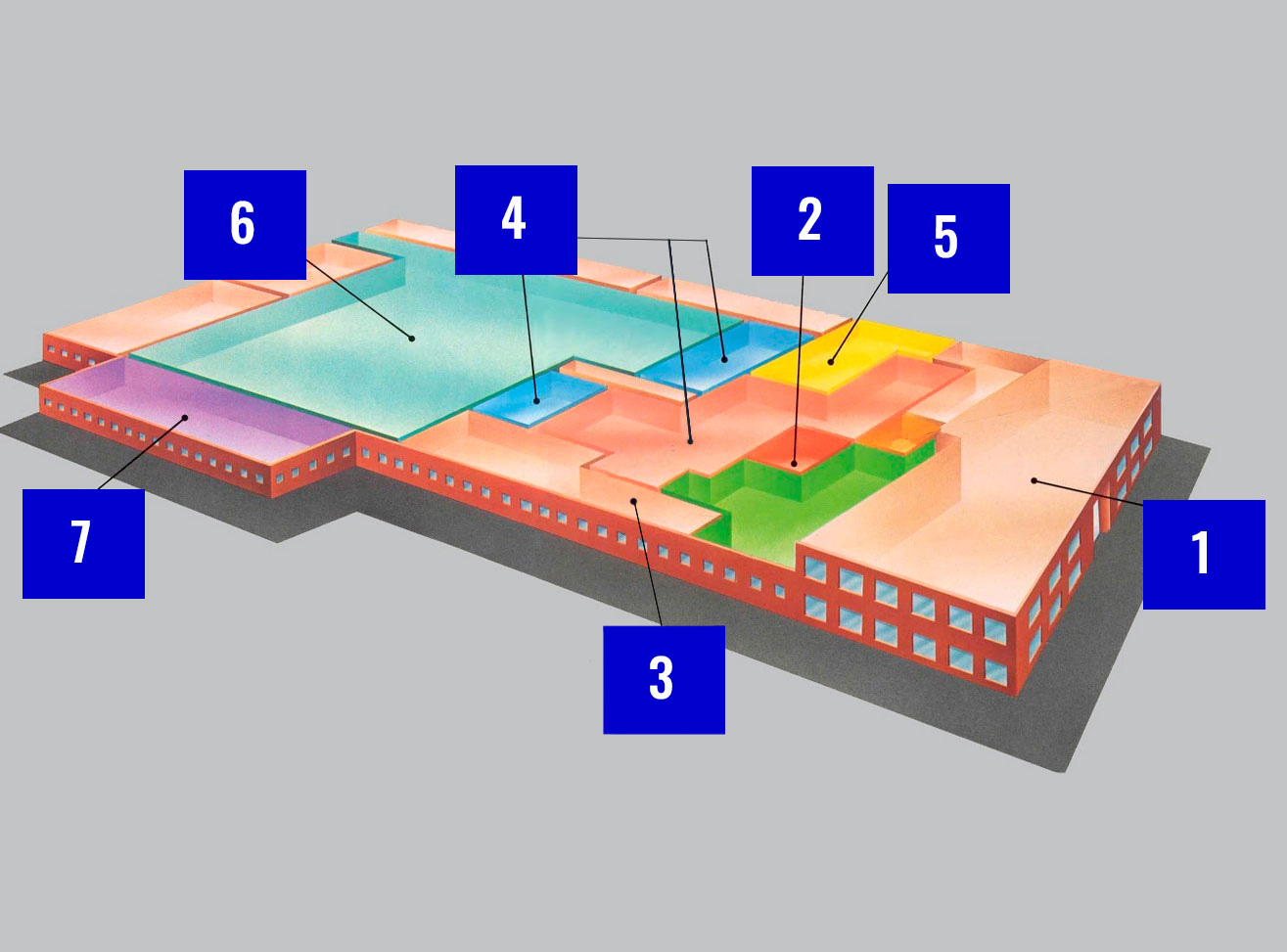

RF Products Facility

RF Products occupies the newest building of what was a 5 building, 2,300 employee factory complex in the TRW days. All RF Products’ critical management, engineering, production, and quality control processes are conducted under this one roof.

Our 90,000 Sq. Ft. plant includes

Management Offices:

- Corporate

- Operations

- Sales & Marketing

R&D Engineering:

- RF

- Electrical

- Mechanical

- Digital

Model Shop:

- Tooling

- Prototypes

Production:

- Engineering

- CAD/CAM

- Parts Fabrication

- Plating & Painting

- Sub-Assembly

- Final Assembly

- Production testing

Quality Control:

- Incoming Inspection & Test

- Environmental & EMI Testing

[ 1 ] Management Offices

Quality Management System in compliance with ISO 9001:2015 and with MIL Q-9858A for design and manufacture of RF communications Equipment and RF Distribution Systems.

[ 2 ] Production Testing

Before shipment, RF Products performs complete testing of all RFD remote control interfaces and waveform timing with actual transceivers, and other customer supplied devices. This reduces to the absolute minimum, any risk of problems for our customers at the platform installations stage.

[ 3 ] Model Shop

Model Shop fabricates production tooling and fixtures. Supports rapid prototyping without impacting producing floor. CNC milling machines, lathes, surface grinders, band saws, drill presses, metal heat treatment, shearing, etc.

[ 4 ] Assembly

One of three assembly areas with parts kits of various products laid out in Kanban fashion to support just-in-time manufacturing including IPC-610 Class 3 Certified Soldering, SMT and Thru-Hole. ESD controls for printed circuit boards. Temperature and humidity control for parts. Wire harness assembly, test and inspection from small 5-wire assemblies to complex 350 wire harnesses.

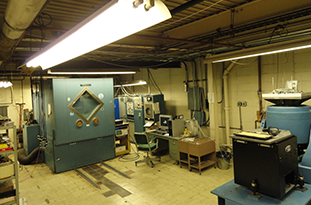

[ 5 ] Environmental Testing

Shown in one of our three environmental test chambers capable of sine and random vibration and temperature testing. In the foreground on the right side is our 3-axis shock and vibration table to support the MIL-STD-810 Qualification test.

[ 6 ] Parts Fabrication

Primary Fabrication and Secondary Operations include CNC parts fabrication, screw machines, punch presses, secondary drilling and tapping operations, in support of low to high volume production rates.

[ 7 ] Plating

Complete in-house capability for silver plating, chemical fil/corrosion prevention, salt-spray, and parts-cleaning operations.

We don’t just have a history of developing RF technologies and radio system designs, we work with you to make sure you get the most out of your communication where it counts – in mission capability. Contact us today to experience the RF Products difference.